Product Description

dc servo motor 24v brushless dc motor 3000rpm 400watt brushless dc motor with encoder for Automatic Xihu (West Lake) Dis.d Vehicle Tracked Robot

Model:KY80AS5714-30

Product overview

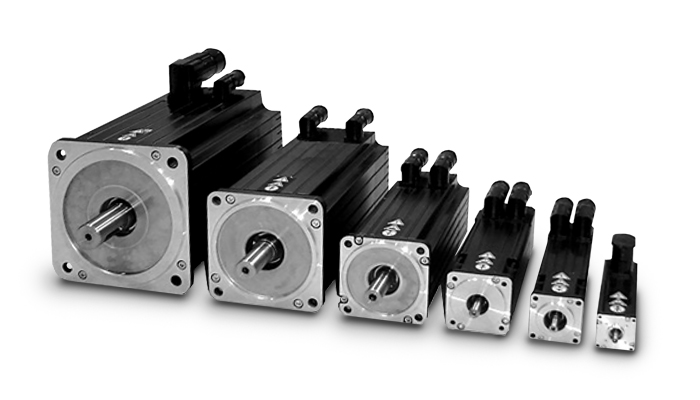

1.Product Features:

1)Protection grade:IP65, insulation grade:F

2)Winding overhang structure optimization, to minimize the copper loss and iron loss minimization, small volume, light weight, low temperature rise, high efficiency

3)Super high coercivity, the maximum magnetic energy product NdFe35 permanent magnetic materials, strong resistance to demagnetization, motor performance is stable.

4)Low noise, low vibration, low moment of inertia.

5)High torque, fast dynamic response, wide speed range, strong overload capacity (four times)

6)High Torque to inertia ratio&up to 25000Nm/kgm²

7)Fast dynamic response *time constant <20ms

8)Wide speed adjusting&feedback up to 1000:1

9)Steady speed precision up to 0.5%

10)High overload,2Mn/30s,3.5N.m/10s

11)Small volume and light

12.Silent,the lowest noise is only 45dB(A)

13.Protected with IP65,Class F insulation

2.Industry class:

a.The altitude should be over 1000 CHINAMFG above sea level

b.Environment temperature:+5ºC~+40ºC

c.The month average tallest relative humidity is 90%,at the same the month average lowest temperature is less than 25

3.Product Parameter:

| Model | KY80AS5714-30 | Volt | 24v |

| Power | 400w |

Rated Torque |

1.27Nm |

|

Rated Speed |

3000rpm |

Rated Current |

18.8A |

|

Peak Torque |

3.8Nm |

Line Resistance |

0.05Ω |

|

Rotor Constant |

0.56mH |

Torque constant |

0.06Nm/A |

|

Back EMF Constant |

10 v/kr/min |

Rotor Inertia |

281Kg.m2×10-6 |

|

Mechanical Time Constant |

0.6ms |

Electrical Time Constant |

0.5ms |

|

Encoder |

2500ppr | Weight | 2.2kg |

4.Related Products:

| Model | Volt | Power | Rated speed | Rated Current | Rated Torque | Peak Torque | Weight |

| Unit | V | W | r/min | A | N.m | N.m | kg |

| KY60AS5711-30 | 24 | 100 | 3000 | 5.4 | 0.318 | 0.95 | 1.5 |

| KY60AS5712-30 | 24 | 200 | 3000 | 10.4 | 0.63 | 1.89 | 1.5 |

| KY80AS5712-15 | 24/48 | 200 | 1500 | 9.4/4.7 | 1.27 | 3.8 | 2.2 |

| KY80AS5714-15 | 24/48 | 400 | 1500 | 21.3/10.6 | 2.55 | 7.65 | 3.6 |

| KY80AS5714-30 | 24/48 | 400 | 3000 | 18.8/9.4 | 1.27 | 3.8 | 2.2 |

| KY110AS0405-15 | 24/48 | 500 | 1500 | 24/14 | 3.1 | 10.8 | 6 |

| KY110AS0408-15 | 24/48 | 800 | 1500 | 44/22 | 5 | 17.9 | 6.6 |

| KY110AS571-15 | 24/48 | 1000 | 1500 | 52/28 | 6.3 | 22 | 7.8 |

| KY110AS571-15 | 48 | 1500 | 1500 | 37.5 | 9.5 | 28 | 10 |

| KY110AS0420-25 | 48 | 2000 | 2500 | 55 | 7.6 | 26 | 10 |

|

KY130AS0430-15 |

48 | 3000 | 1500 | 73 | 19 | 57 | 14 |

|

KY130AS571-15 |

48 | 1000 | 1500 | 28 | 6.3 | 22 | 7.8 |

| KY130AS571-15 | 48 | 1500 | 1500 | 37.5 | 9.5 | 28 | 10 |

FAQ

Q: What are your main products?

A: We produce various kinds of dc motor & controller.

Q: Is there a MOQ for your motor controller?

A: There is no MOQ requirement. But the more the better.

Q: How do you ensure the product quality?

A: We have strict test system in every link of material selection, production and final product, packing according to ISO9001 management.

Q: Is it possible for you to develop new controllers if we provide the tooling cost?

A: Yes. Please kindly share the detailed requirements like performance, size, annual quantity, target price etc. Then we’ll make our evaluation to see if we can arrange or not.

Q: How soon can you deliver the goods?

A: That depends on the exact model you order. For regular products, usually we will prepare some units in stock, we can deliver them within 3 working days.

Application

| Application: | Universal, Industrial, Car, Electric Vehicle |

|---|---|

| Operating Speed: | Adjust Speed |

| Excitation Mode: | Excited |

| Function: | Control, Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 10 |

| Samples: |

US$ 110/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for ensuring the longevity of servo motors?

Maintaining servo motors properly is crucial to ensure their longevity and reliable performance. Here are some recommended maintenance practices:

1. Regular Cleaning:

Regularly clean the servo motor to remove dust, debris, and other contaminants that can affect its performance. Use a soft brush or compressed air to clean the motor’s exterior and ventilation ports. Avoid using excessive force or liquid cleaners that could damage the motor.

2. Lubrication:

Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant for the motor. Lubricate the motor’s bearings, gears, and other moving parts as per the specified schedule. Proper lubrication reduces friction, minimizes wear, and helps maintain optimal performance.

3. Inspections:

Regularly inspect the servo motor for signs of wear, damage, or loose connections. Check for any unusual noises, vibrations, or overheating during operation, as these can indicate potential issues. If any abnormalities are detected, consult the manufacturer’s documentation or seek professional assistance for further evaluation and repair.

4. Electrical Connections:

Ensure that all electrical connections to the servo motor, such as power cables and signal wires, are secure and properly insulated. Loose or damaged connections can lead to electrical problems, voltage fluctuations, or signal interference, which can affect the motor’s performance and longevity.

5. Environmental Considerations:

Take into account the operating environment of the servo motor. Ensure that the motor is protected from excessive moisture, dust, extreme temperatures, and corrosive substances. If necessary, use appropriate enclosures or protective measures to safeguard the motor from adverse environmental conditions.

6. Software and Firmware Updates:

Stay updated with the latest software and firmware releases provided by the servo motor manufacturer. These updates often include bug fixes, performance enhancements, and new features that can improve the motor’s functionality and reliability. Follow the manufacturer’s instructions for safely updating the motor’s software or firmware.

7. Training and Documentation:

Ensure that personnel responsible for the maintenance of servo motors are properly trained and familiar with the manufacturer’s guidelines and documentation. This includes understanding recommended maintenance procedures, safety precautions, and troubleshooting techniques. Regular training and access to up-to-date documentation are essential for effective servo motor maintenance.

8. Professional Servicing:

If a servo motor requires complex repairs or servicing beyond regular maintenance, it is advisable to consult a qualified technician or contact the manufacturer’s service center. Attempting to repair or modify the motor without proper expertise can lead to further damage or safety hazards.

By following these maintenance practices, servo motors can operate optimally and have an extended lifespan. Regular cleaning, lubrication, inspections, secure electrical connections, environmental considerations, software updates, training, and professional servicing all contribute to ensuring the longevity and reliable performance of servo motors.

Are there different types of servo motors, and how do they differ?

Yes, there are different types of servo motors available, each with its own characteristics and applications. The variations among servo motors can be attributed to factors such as construction, control mechanisms, power requirements, and performance specifications. Let’s explore some of the common types of servo motors and how they differ:

1. DC Servo Motors:

DC servo motors are widely used in various applications. They consist of a DC motor combined with a feedback control system. The control system typically includes a position or velocity feedback sensor, such as an encoder or a resolver. DC servo motors offer good speed and torque control and are often employed in robotics, automation, and hobbyist projects. They can be operated with a separate motor driver or integrated into servo motor units with built-in control electronics.

2. AC Servo Motors:

AC servo motors are designed for high-performance applications that require precise control and fast response times. They are typically three-phase motors and are driven by sinusoidal AC waveforms. AC servo motors often incorporate advanced control algorithms and feedback systems to achieve accurate position, velocity, and torque control. These motors are commonly used in industrial automation, CNC machines, robotics, and other applications that demand high precision and dynamic performance.

3. Brushed Servo Motors:

Brushed servo motors feature a traditional brushed DC motor design. They consist of a rotor with a commutator and carbon brushes that make physical contact with the commutator. The brushes provide electrical connections, allowing the motor’s magnetic field to interact with the rotor’s windings. Brushed servo motors are known for their simplicity and cost-effectiveness. However, they may require more maintenance due to brush wear, and they generally have lower efficiency and shorter lifespan compared to brushless servo motors.

4. Brushless Servo Motors:

Brushless servo motors, also known as brushless DC (BLDC) motors, offer several advantages over brushed motors. They eliminate the need for brushes and commutators, resulting in improved reliability, higher efficiency, and longer lifespan. Brushless servo motors rely on electronic commutation, typically using Hall effect sensors or encoder feedback for accurate rotor position detection. These motors are widely used in robotics, industrial automation, aerospace, and other applications that require high-performance motion control with minimal maintenance.

5. Linear Servo Motors:

Linear servo motors are designed to provide linear motion instead of rotational motion. They consist of a primary part (stator) and a secondary part (slider or forcer) that interact magnetically to generate linear motion. Linear servo motors offer advantages such as high speed, high acceleration, and precise positioning along a linear axis. They find applications in various industries, including semiconductor manufacturing, packaging, printing, and machine tools.

6. Micro Servo Motors:

Micro servo motors are small-sized servo motors often used in applications with limited space and low power requirements. They are commonly found in hobbyist projects, model airplanes, remote-controlled vehicles, and small robotic systems. Micro servo motors are lightweight, compact, and offer reasonable precision and control for their size.

These are some of the different types of servo motors available, each catering to specific applications and requirements. The choice of servo motor type depends on factors such as the desired performance, accuracy, power requirements, environmental conditions, and cost considerations. Understanding the differences between servo motor types is essential for selecting the most suitable motor for a particular application.

What is a servo motor, and how does it function in automation systems?

A servo motor is a type of motor specifically designed for precise control of angular or linear position, velocity, and acceleration. It is widely used in various automation systems where accurate motion control is required. Let’s explore the concept of servo motors and how they function in automation systems:

A servo motor consists of a motor, a position feedback device (such as an encoder or resolver), and a control system. The control system receives input signals, typically in the form of electrical pulses or analog signals, indicating the desired position or speed. Based on these signals and the feedback from the position sensor, the control system adjusts the motor’s operation to achieve the desired motion.

The functioning of a servo motor in an automation system involves the following steps:

- Signal Input: The automation system provides a control signal to the servo motor, indicating the desired position, speed, or other motion parameters. This signal can be generated by a human operator, a computer, a programmable logic controller (PLC), or other control devices.

- Feedback System: The servo motor incorporates a position feedback device, such as an encoder or resolver, which continuously monitors the motor’s actual position. This feedback information is sent back to the control system, allowing it to compare the actual position with the desired position specified by the input signal.

- Control System: The control system, typically housed within the servo motor or an external servo drive, receives the input signal and the feedback from the position sensor. It processes this information and generates the appropriate control signals to the motor.

- Motor Operation: Based on the control signals received from the control system, the servo motor adjusts its operation to achieve the desired motion. The control system varies the motor’s voltage, current, or frequency to control the motor’s speed, torque, or position accurately.

- Closed-Loop Control: Servo motors operate in a closed-loop control system. The feedback information from the position sensor allows the control system to continuously monitor and adjust the motor’s operation to minimize any deviation between the desired position and the actual position. This closed-loop control mechanism provides high accuracy, repeatability, and responsiveness in motion control applications.

One of the key advantages of servo motors in automation systems is their ability to provide precise and dynamic motion control. They can rapidly accelerate, decelerate, and change direction with high accuracy, allowing for intricate and complex movements. Servo motors are widely used in applications such as robotics, CNC machines, printing presses, packaging equipment, and automated manufacturing systems.

In summary, a servo motor is a specialized motor that enables accurate control of position, velocity, and acceleration in automation systems. Through the combination of a control system and a position feedback device, servo motors can precisely adjust their operation to achieve the desired motion. Their closed-loop control mechanism and high responsiveness make them an essential component in various applications requiring precise and dynamic motion control.

editor by CX 2023-12-11