Product Description

| Product Name | Steering Servo Motor |

| Model Number | 110SYT002 |

| Application | Electrical vehicle, HELI 16S forwarding forklift |

| Lifttop Code | A.D.03.5717Y |

Packaging & Shipping

Packing Details: Foam Protection, Individually Bagged, Packed into boxes, Standard Packing: Boxes+ Carton+ Pallet Packing or According to customers’ requirement

Delivery Details: 7-10 working days after down payment received

1. By Couriers: DHL, UPS, FEDEX, TNT are the main courier companies we are cooperated,

2. By Air: Delivery from the ZheJiang air port to customer’s destination city air port.

3. By Sea: Delivery from the ZheJiang sea port.

About Us

ZheJiang CHINAMFG Imp. & Exp. Co., Ltd is located in HangZhou city, we specializing in spare parts of material handling equipment, forklift and golf cart for more than 16 years experience. Product categories include controlling system, drive system, transmission system, hydraulic system, and product variety is more than 5000 relating to controllers, motors, contactors, connectors, sensors, battery charger etc. We have developed to the top supplier for forklift parts in the past years. And the parts we offer can meet the request of different brands forklifts in the market such as TCM, TOYOTA, NICHIYU, NISSAN, MITSUBISHI, LINDE, HYSTER, DAEWOO, TAILIFT, HELI, HANGCHA, JAC, BAOLI etc.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: What is your advantages?

A: * * A manufacture with 15 years experiences

* * Free samples are accepted

* * Customized sizes are accepted

* * Most types and sizes are in stock

* * Fast delivery and production

Q: How to order?

A: Please contact me through email, Tel, or , tell me what you need and I will offer according to your requirement .After you confirm, I will send PI for payment .

Q: How to produce?

A: We can produce according to seal type and sizes.

If you need some customized parts, we can produce according to drawing and samples.

Q: How to deliver?

A: For small order, we will deliver by express, such as DHL, FEDEX, UPS, TNT. etc

for large order , we can deliver by air or by ship .

Q: About payment?

A: We accept: T/T, Paypal, Western Union, Money Gram.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 3 Months |

|---|---|

| Material: | Metal |

| Surface Treatment: | None |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How are servo motors used in CNC machines and other precision machining equipment?

Servo motors play a crucial role in CNC (Computer Numerical Control) machines and other precision machining equipment. They provide precise and dynamic control over the movement of various axes, enabling high-accuracy positioning, rapid speed changes, and smooth motion profiles. Here’s a detailed explanation of how servo motors are used in CNC machines and precision machining equipment:

1. Axis Control:

CNC machines typically have multiple axes, such as X, Y, and Z for linear movements, as well as rotary axes for rotational movements. Servo motors are employed to drive each axis, converting electrical signals from the CNC controller into mechanical motion. The position, velocity, and acceleration of the servo motors are precisely controlled to achieve accurate and repeatable positioning of the machine’s tool or workpiece.

2. Feedback and Closed-Loop Control:

Servo motors in CNC machines are equipped with feedback devices, such as encoders or resolvers, to provide real-time information about the motor’s actual position. This feedback is used in a closed-loop control system, where the CNC controller continuously compares the desired position with the actual position and adjusts the motor’s control signals accordingly. This closed-loop control ensures accurate positioning and compensates for any errors, such as mechanical backlash or load variations.

3. Rapid and Precise Speed Changes:

Servo motors offer excellent dynamic response, allowing CNC machines to achieve rapid and precise speed changes during machining operations. By adjusting the control signals to the servo motors, the CNC controller can smoothly accelerate or decelerate the machine’s axes, resulting in efficient machining processes and reduced cycle times.

4. Contouring and Path Tracing:

CNC machines often perform complex machining tasks, such as contouring or following intricate paths. Servo motors enable precise path tracing by accurately controlling the position and velocity of the machine’s tool along the programmed path. This capability is crucial for producing intricate shapes, smooth curves, and intricate details with high precision.

5. Spindle Control:

In addition to axis control, servo motors are also used to control the spindle in CNC machines. The spindle motor, typically a servo motor, rotates the cutting tool or workpiece at the desired speed. Servo control ensures precise speed and torque control, allowing for optimal cutting conditions and surface finish quality.

6. Tool Changers and Automatic Tool Compensation:

CNC machines often feature automatic tool changers to switch between different cutting tools during machining operations. Servo motors are utilized to precisely position the tool changer mechanism, enabling quick and accurate tool changes. Additionally, servo motors can be used for automatic tool compensation, adjusting the tool’s position or orientation to compensate for wear, tool length variations, or tool offsets.

7. Synchronized Motion and Multi-Axis Coordination:

Servo motors enable synchronized motion and coordination between multiple axes in CNC machines. By precisely controlling the servo motors on different axes, complex machining operations involving simultaneous movements can be achieved. This capability is vital for tasks such as 3D contouring, thread cutting, and multi-axis machining.

In summary, servo motors are integral components of CNC machines and precision machining equipment. They provide accurate and dynamic control over the machine’s axes, enabling high-precision positioning, rapid speed changes, contouring, spindle control, tool changers, and multi-axis coordination. The combination of servo motor technology and CNC control systems allows for precise, efficient, and versatile machining operations in various industries.

What factors should be considered when selecting a servo motor for a specific application?

When selecting a servo motor for a specific application, several factors need to be considered. These factors help ensure that the chosen servo motor meets the requirements and performs optimally in the intended application. Here are some key factors to consider:

1. Torque and Power Requirements:

One of the primary considerations is the torque and power requirements of the application. The servo motor should be able to generate sufficient torque to handle the load and overcome any resistance or friction in the system. Additionally, the power rating of the motor should match the power supply available in the application. It is essential to evaluate the torque-speed characteristics of the servo motor to ensure it can deliver the required performance.

2. Speed and Acceleration:

The required speed and acceleration capabilities of the servo motor should align with the application’s needs. Different applications have varying speed and acceleration requirements, and the servo motor should be able to meet these demands. It is crucial to consider both the maximum speed that the motor can achieve and the time it takes to accelerate or decelerate to specific speeds. Evaluating the servo motor’s speed-torque characteristics and acceleration capabilities is necessary for selecting the right motor.

3. Positioning Accuracy and Repeatability:

The desired positioning accuracy and repeatability of the application play a significant role in servo motor selection. If precise positioning is crucial, a servo motor with high accuracy and low positioning errors should be chosen. The feedback mechanism, such as encoders or resolvers, should provide the required resolution to achieve the desired accuracy. Repeatability, the ability to consistently reach the same position, should also be considered, especially in applications where repetitive movements are necessary.

4. Environmental Conditions:

The environmental conditions in which the servo motor will operate should be taken into account. Factors such as temperature extremes, humidity, dust, and vibration can affect the motor’s performance and lifespan. In harsh environments, it may be necessary to choose a servo motor with appropriate protection ratings, such as IP (Ingress Protection) ratings, to ensure reliable operation and longevity.

5. Control System Compatibility:

The compatibility of the servo motor with the control system used in the application is crucial. The motor should be compatible with the control signals and communication protocols employed in the system. This includes considerations such as voltage compatibility, control signal types (analog, digital, pulse), and communication interfaces (such as Ethernet, CAN, or Modbus). Ensuring compatibility will facilitate seamless integration and efficient control of the servo motor within the application.

6. Size and Weight Constraints:

The physical size and weight limitations of the application should be considered when selecting a servo motor. The motor’s dimensions should fit within the available space, and its weight should not exceed the application’s weight capacity. Compact and lightweight servo motors may be preferred in applications where space is limited or weight is a critical factor.

7. Cost Considerations:

The cost of the servo motor and its overall value for the application should be evaluated. It is essential to consider the initial purchase cost as well as the long-term maintenance and operational costs. While cost is a factor, it should not be the sole determining factor, as compromising on quality or performance may lead to suboptimal results.

By considering these factors, one can make an informed decision when selecting a servo motor for a specific application. It is recommended to consult with manufacturers or experts in the field to ensure the chosen servo motor meets the application’s requirements and provides reliable and efficient performance.

What is a servo motor, and how does it function in automation systems?

A servo motor is a type of motor specifically designed for precise control of angular or linear position, velocity, and acceleration. It is widely used in various automation systems where accurate motion control is required. Let’s explore the concept of servo motors and how they function in automation systems:

A servo motor consists of a motor, a position feedback device (such as an encoder or resolver), and a control system. The control system receives input signals, typically in the form of electrical pulses or analog signals, indicating the desired position or speed. Based on these signals and the feedback from the position sensor, the control system adjusts the motor’s operation to achieve the desired motion.

The functioning of a servo motor in an automation system involves the following steps:

- Signal Input: The automation system provides a control signal to the servo motor, indicating the desired position, speed, or other motion parameters. This signal can be generated by a human operator, a computer, a programmable logic controller (PLC), or other control devices.

- Feedback System: The servo motor incorporates a position feedback device, such as an encoder or resolver, which continuously monitors the motor’s actual position. This feedback information is sent back to the control system, allowing it to compare the actual position with the desired position specified by the input signal.

- Control System: The control system, typically housed within the servo motor or an external servo drive, receives the input signal and the feedback from the position sensor. It processes this information and generates the appropriate control signals to the motor.

- Motor Operation: Based on the control signals received from the control system, the servo motor adjusts its operation to achieve the desired motion. The control system varies the motor’s voltage, current, or frequency to control the motor’s speed, torque, or position accurately.

- Closed-Loop Control: Servo motors operate in a closed-loop control system. The feedback information from the position sensor allows the control system to continuously monitor and adjust the motor’s operation to minimize any deviation between the desired position and the actual position. This closed-loop control mechanism provides high accuracy, repeatability, and responsiveness in motion control applications.

One of the key advantages of servo motors in automation systems is their ability to provide precise and dynamic motion control. They can rapidly accelerate, decelerate, and change direction with high accuracy, allowing for intricate and complex movements. Servo motors are widely used in applications such as robotics, CNC machines, printing presses, packaging equipment, and automated manufacturing systems.

In summary, a servo motor is a specialized motor that enables accurate control of position, velocity, and acceleration in automation systems. Through the combination of a control system and a position feedback device, servo motors can precisely adjust their operation to achieve the desired motion. Their closed-loop control mechanism and high responsiveness make them an essential component in various applications requiring precise and dynamic motion control.

editor by CX 2024-04-24

China Professional 12V DC Electric Servo Motor Linear Actuator for Reclining Sofas & Couches Parts with Great quality

Product Description

Product Description

The actuator consists of a motor, a ball screw, and a nut. The motor provides the rotational force, which is transmitted to the ball screw via a coupling. The ball screw, in turn, converts the rotary motion into linear motion using a series of ball bearings that recirculate within the nut. This design allows for smooth and efficient movement with minimal friction.

Product Parameters

| Linear Actuator | DGRST55 | ||

| Ball Screw | Screw Lead 10mm Diameter 16mm Rated Dynamic Load 1380kgf |

||

| Max. Motor Power | w | 400w Servo Motor Rated Torque 1.27Nm Rated Speed 3000rpm |

|

| Reducation | 1 | 1.5 | |

| Max. Rated Speed | mm/s | 250 | 166 |

| Max. Rated Thrust | N | 1360 | 2030 |

| Max. Rated Torque | N.m | 1.27 | 1.91 |

| Stroke Range | mm | 10-800mm | |

| Inline Type | √ | x | |

| Parallel Type | √ | √ | |

Detailed Photos

Applications

Our Advantages

Careful Material Selection1. Use round carbon steel as the cylinder material

2. Select sensor components of internationally famous brands.

3. Key components are made of high-quality materials and processed with vacuum heat treatment or surface treatment (including coating, azotizing, oxidation)

4. Select branded bearings and gears to achieve the best mechanical performance in mechanical structure

5. Select high-quality grease to minimize friction, which enables the drive efficiency to reach up to 90%.Refined Design and Processing1. The connection between the screw nut and the piston rod is rigid

2. Snap fastener will be required to locate the part in its fixed position to avoid assembly errors that affect mechanical properties.

3. All screw threads are coated with screw locking adhesive after commissioning to ensure the equipment is stable and trouble-free.

4. Adopt domestic ball screw and bearing products, light load output, high-cost performance

5. All heavy-duty cylinders use sliding key guides. (The square cylinders are using guided rod)

FAQ

Q1. What are your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown wooden cartons. If you have a legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What are your terms of payment?

A: T/T 50% as deposit, and 50% before shipping. We’ll show you the photos of the products and packages before

you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 10-25 days to produce the products, and 5days by air, 25 days of the ship by sea. The specific delivery time depends on the items and the quantity of your order.

Q5: How is the warranty system?

A: 1~5 years. (upon the deal)

Q6. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q7. What is your sample policy?

A: We can supply the sample, but the customers have to pay the sample cost and the courier cost.

Q8. Do you test all your goods before delivery?

A: Yes, we have a 100% test before delivery.

Packaging & Shipping

| 1, Plastic Packaging | 2, Foam Protection | 3, Carton Packaging |

| 4, Wooden Box Packaging | 5, Packaging Completed | 6, Shipping |

Notes

1.If you need to know the ball screw life, please contact customer service for detailed consultation;

2.The max. thrust and the max. speed can not be reached at the same time. Different motor and gear boxes will be used.

3.If the Max. stroke exceeds 500mm, it is recommended to add a guiding device;

Note: If above parameters can not meet your needs, please contact us, we can customize according to your requirements with NO MOQ.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO, CE |

|---|---|

| IP Rating: | IP65 |

| Limit Switch: | Built-in |

| Voltage: | DC / AC |

| Standard Stroke: | 10-800mm |

| Max Thrust: | 2000N |

| Customization: |

Available

|

|

|---|

What role does the controller play in the overall performance of a servo motor?

The controller plays a crucial role in the overall performance of a servo motor system. It is responsible for monitoring and regulating the motor’s operation to achieve the desired motion and maintain system stability. Let’s explore in detail the role of the controller in the performance of a servo motor:

1. Motion Control:

The controller is responsible for generating precise control signals that dictate the motor’s speed, torque, and position. It receives input commands from the user or higher-level control system and translates them into appropriate control signals for the servo motor. By accurately controlling the motor’s motion, the controller enables precise positioning, smooth acceleration and deceleration, and the ability to follow complex trajectories. The controller’s effectiveness in generating accurate and responsive control signals directly impacts the motor’s motion control capabilities.

2. Feedback Control:

The controller utilizes feedback from position sensors, such as encoders, to monitor the motor’s actual position, speed, and other parameters. It compares the desired motion profile with the actual motor behavior and continuously adjusts the control signals to minimize any deviations or errors. This closed-loop feedback control mechanism allows the controller to compensate for disturbances, variations in load conditions, and other factors that may affect the motor’s performance. By continuously monitoring and adjusting the control signals based on feedback, the controller helps maintain accurate and stable motor operation.

3. PID Control:

Many servo motor controllers employ Proportional-Integral-Derivative (PID) control algorithms to regulate the motor’s behavior. PID control calculates control signals based on the error between the desired setpoint and the actual motor response. The proportional term responds to the present error, the integral term accounts for accumulated past errors, and the derivative term considers the rate of change of the error. By tuning the PID parameters, the controller can achieve optimal performance in terms of response time, stability, and steady-state accuracy. Properly configured and tuned PID control greatly influences the servo motor’s ability to follow commands accurately and efficiently.

4. Trajectory Planning:

In applications requiring complex motion profiles or trajectories, the controller plays a vital role in trajectory planning. It determines the optimal path and speed profile for the motor to follow, taking into account constraints such as acceleration limits, jerk limits, and mechanical limitations. The controller generates the required control signals to achieve the desired trajectory, ensuring smooth and precise motion. Effective trajectory planning by the controller enhances the motor’s performance in applications that involve intricate or high-speed movements.

5. System Monitoring and Protection:

The controller monitors various parameters of the servo motor system, including temperature, current, voltage, and other diagnostic information. It incorporates protective measures to prevent damage or excessive stress on the motor. The controller can implement safety features such as overcurrent protection, over-temperature protection, and fault detection mechanisms. By actively monitoring and safeguarding the motor and the system, the controller helps prevent failures, prolongs the motor’s lifespan, and ensures safe and reliable operation.

6. Communication and Integration:

The controller facilitates communication and integration with other components or systems within the overall automation setup. It may support various communication protocols, such as Ethernet, CAN bus, or fieldbus protocols, enabling seamless integration with higher-level control systems, human-machine interfaces (HMIs), or other peripheral devices. The controller’s ability to efficiently exchange data and commands with other system components allows for coordinated and synchronized operation, enhancing the overall performance and functionality of the servo motor system.

In summary, the controller plays a vital role in the overall performance of a servo motor system. It enables precise motion control, utilizes feedback for closed-loop control, implements PID control algorithms, plans complex trajectories, monitors system parameters, and facilitates communication and integration. The controller’s capabilities and effectiveness directly impact the motor’s performance in terms of accuracy, responsiveness, stability, and overall system efficiency.

What factors should be considered when selecting a servo motor for a specific application?

When selecting a servo motor for a specific application, several factors need to be considered. These factors help ensure that the chosen servo motor meets the requirements and performs optimally in the intended application. Here are some key factors to consider:

1. Torque and Power Requirements:

One of the primary considerations is the torque and power requirements of the application. The servo motor should be able to generate sufficient torque to handle the load and overcome any resistance or friction in the system. Additionally, the power rating of the motor should match the power supply available in the application. It is essential to evaluate the torque-speed characteristics of the servo motor to ensure it can deliver the required performance.

2. Speed and Acceleration:

The required speed and acceleration capabilities of the servo motor should align with the application’s needs. Different applications have varying speed and acceleration requirements, and the servo motor should be able to meet these demands. It is crucial to consider both the maximum speed that the motor can achieve and the time it takes to accelerate or decelerate to specific speeds. Evaluating the servo motor’s speed-torque characteristics and acceleration capabilities is necessary for selecting the right motor.

3. Positioning Accuracy and Repeatability:

The desired positioning accuracy and repeatability of the application play a significant role in servo motor selection. If precise positioning is crucial, a servo motor with high accuracy and low positioning errors should be chosen. The feedback mechanism, such as encoders or resolvers, should provide the required resolution to achieve the desired accuracy. Repeatability, the ability to consistently reach the same position, should also be considered, especially in applications where repetitive movements are necessary.

4. Environmental Conditions:

The environmental conditions in which the servo motor will operate should be taken into account. Factors such as temperature extremes, humidity, dust, and vibration can affect the motor’s performance and lifespan. In harsh environments, it may be necessary to choose a servo motor with appropriate protection ratings, such as IP (Ingress Protection) ratings, to ensure reliable operation and longevity.

5. Control System Compatibility:

The compatibility of the servo motor with the control system used in the application is crucial. The motor should be compatible with the control signals and communication protocols employed in the system. This includes considerations such as voltage compatibility, control signal types (analog, digital, pulse), and communication interfaces (such as Ethernet, CAN, or Modbus). Ensuring compatibility will facilitate seamless integration and efficient control of the servo motor within the application.

6. Size and Weight Constraints:

The physical size and weight limitations of the application should be considered when selecting a servo motor. The motor’s dimensions should fit within the available space, and its weight should not exceed the application’s weight capacity. Compact and lightweight servo motors may be preferred in applications where space is limited or weight is a critical factor.

7. Cost Considerations:

The cost of the servo motor and its overall value for the application should be evaluated. It is essential to consider the initial purchase cost as well as the long-term maintenance and operational costs. While cost is a factor, it should not be the sole determining factor, as compromising on quality or performance may lead to suboptimal results.

By considering these factors, one can make an informed decision when selecting a servo motor for a specific application. It is recommended to consult with manufacturers or experts in the field to ensure the chosen servo motor meets the application’s requirements and provides reliable and efficient performance.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

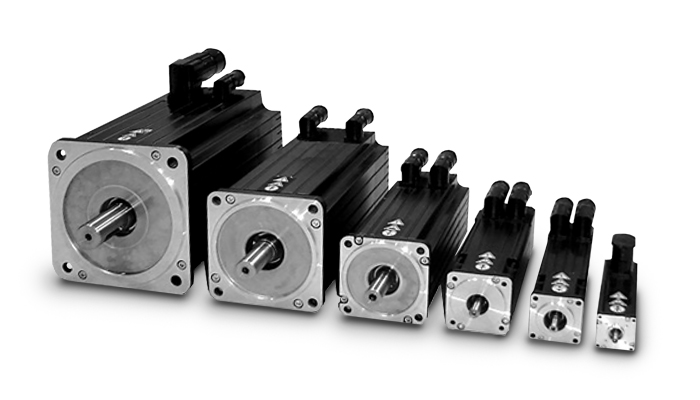

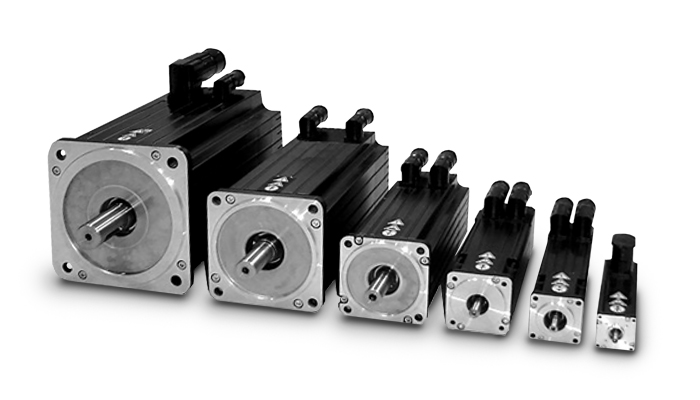

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-04-11

China Construction Machinery Excavator Spare Parts Kubota U15 Slewing Motors Eaton 2-200DOS-E3 U17 Swing Motor motor electric

Product Description

Excavator Parts CZPT U15 Slewing Motors 2-2, 6655458, 6658535.

MX225 final drive travel motor 6652841, 6692633.

MX231 final drive travel motor 6670667

MX316 final drive travel motor NTS5-58

MX320 final drive travel motor 6651892, 6667336.

MX321 final drive travel motor 6688447

MX322 final drive travel motor 6651892, 6667336.

MX323 final drive travel motor 6686~8, 6688447.

MX324 final drive travel motor 6688447

MX325 final drive travel motor 6692633, 6652841, 6668135.

MX328 final drive travel motor 6692633, 6668135.

MX329 final drive travel motor 6689642, 6689482.

MX331 final drive travel motor 6670667, 6677666.

MX334 final drive travel motor 6670667, 6677666.

MX337 final drive travel motor 6668730

MX341 final drive travel motor 6668730

MX418 final drive travel motor 6691262, 6691107.

MX425 final drive travel motor 6677666

MX428 final drive travel motor 6677666

MX430 final drive travel motor 6683380, 6691497, 6685454.

MX442 final drive travel motor,

MX444 final drive travel motor

E10 final drive travel motor 6691262, 6691107.

E14 final drive travel motor 6685976

E16 final drive travel motor 6688447

E19 final drive travel motor 7245682

E20 final drive travel motor 7245682

E25 final drive travel motor 719571

E26 final drive travel motor 719571

E27 final drive travel motor 719571

E32 final drive travel motor 6698127

E35 final drive travel motor 6698127

E42 final drive travel motor 6691497

E45 final drive travel motor 7012323

E50 final drive travel motor 6668730

E55 final drive travel motor 6668730

E80 final drive travel motor 7006068

We could supply the following spare parts.

1. Hydraulic parts: hydraulic pump, main control valve, hydraulic cylinder, final drive travel motor, swing motor reducer gearbox, etc.

2. Engine parts: engine ass’y, piston, piston ring, cylinder block, cylinder head, crankshaft, turbocharger, fuel injection pump,

starting motor and alternator etc.

3. Undercarriage parts: Track roller, Carrier roller, Track Link, Track shoe, Sprocket, Idler and Idler cushion etc.

4. Cab parts: operator’s cab, wiring harness, monitor, controller, seat, door etc.

5. Other parts: Service kit, swing circle, engine hood, swivel joint, fuel tank, filter, boom, arm, bucket etc.

PACKAGE:

Standard export wooden case or carton packing.

DELIVERY TIME:

1-3 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

FAQ:

Q: When will ship my order?

A: Once we get confirmation of payment, we will try our best to ship order within 24 hours.

Q: How long does it take to my address?

A: The Normal delivery time is 4-7 days, depending on which country you are in.

Q: How can I track my order?

A: We will send you the tracking number by email.

Q: If I am not satisfied with the products, can I returns goods?

A: Yes, we offer exchange and repair service under warranty. Please contact us before you want to return.

|

US $1,050-1,200 / Piece | |

1 Piece (Min. Order) |

###

| After-sales Service: | Free Spare Parts, Video Technical Support |

|---|---|

| Warranty: | 1 Year |

| Type: | Motor |

| Application: | Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

###

| Customization: |

Available

|

|---|

###

| Product name | Kubota U15 U17 swing motor |

| Condition | 100% new |

| Brand | Eaton |

| MOQ | 1 piece |

| Size | 12 teeth |

| Weight | 20KG |

| Delivery time | within 3 days |

| Payment term | TT,Western Union,Online payment |

| Warranty time | 1 year |

|

US $1,050-1,200 / Piece | |

1 Piece (Min. Order) |

###

| After-sales Service: | Free Spare Parts, Video Technical Support |

|---|---|

| Warranty: | 1 Year |

| Type: | Motor |

| Application: | Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

###

| Customization: |

Available

|

|---|

###

| Product name | Kubota U15 U17 swing motor |

| Condition | 100% new |

| Brand | Eaton |

| MOQ | 1 piece |

| Size | 12 teeth |

| Weight | 20KG |

| Delivery time | within 3 days |

| Payment term | TT,Western Union,Online payment |

| Warranty time | 1 year |

The Benefits of Using a Gear Motor

A gear motor works on the principle of conservation of angular momentum. As the smaller gear covers more RPM and the larger gear produces more torque, the ratio between the two is greater than one. Similarly, a multiple gear motor follows the principle of energy conservation, with the direction of rotation always opposite to the one that is adjacent to it. It’s easy to understand the concept behind gear motors and the various types available. Read on to learn about the different types of gears and their applications.

Electric motor

The choice of an electric motor for gear motor is largely dependent on the application. There are various motor and gearhead combinations available, and some are more efficient than others. However, it is critical to understand the application requirements and select a motor that meets these needs. In this article, we’ll examine some of the benefits of using a gear motor. The pros and cons of each type are briefly discussed. You can buy new gear motors at competitive prices, but they aren’t the most reliable or durable option for your application.

To determine which motor is best for your application, you’ll need to consider the load and speed requirements. A gear motor’s efficiency (e) can be calculated by taking the input and output values and calculating their relation. On the graph below, the input (T) and output (P) values are represented as dashed lines. The input (I) value is represented as the torque applied to the motor shaft. The output (P) is the amount of mechanical energy converted. A DC gear motor is 70% efficient at 3.75 lb-in / 2,100 rpm.

In addition to the worm gear motor, you can also choose a compact DC worm gear motor with a variable gear ratio from 7.5 to 80. It has a range of options and can be custom-made for your specific application. The 3-phase AC gear motor, on the other hand, works at a rated power of one hp and torque of 1.143.2 kg-m. The output voltage is typically 220V.

Another important factor is the output shaft orientation. There are two main orientations for gearmotors: in-line and offset. In-line output shafts are most ideal for applications with high torque and short reduction ratios. If you want to avoid backlash, choose a right angle output shaft. An offset shaft can cause the output shaft to become excessively hot. If the output shaft is angled at a certain angle, it may be too large or too small.

Gear reducer

A gear reducer is a special kind of speed reducing motor, usually used in large machinery, such as compressors. These reducers have no cooling fan and are not designed to handle heavy loads. Different purposes require different service factors. For instance, a machine that requires frequent fast accelerations and occasional load spikes needs a gear reducer with a high service factor. A gear reducer that’s designed for long production shifts should be larger than a machine that uses it for short periods of time.

A gear reducer can reduce the speed of a motor by a factor of two. The reduction ratio changes the rotation speed of the receiving member. This change in speed is often required to solve problems of inertia mismatch. The torque density of a gear reducer is measured in newton meters and will depend on the motor used. The first criterion is the configuration of the input and output shafts. A gear ratio of 2:1, for example, means that the output speed has been cut in half.

Bevel gear reducers are a good option if the input and output shafts are perpendicular. This type is very robust and is perfect for situations where the angle between two axes is small. However, bevel gear reducers are expensive and require constant maintenance. They are usually used in heavy-duty conveyors and farm equipment. The correct choice of gear reducer for gear motor is crucial for the efficiency and reliability of the mechanism. To get the best gear reducer for your application, talk to a qualified manufacturer today.

Choosing a gear reducer for a gear motor can be tricky. The wrong one can ruin an entire machine, so it’s important to know the specifics. You must know the torque and speed requirements and choose a motor with the appropriate ratio. A gear reducer should also be compatible with the motor it’s intended for. In some cases, a smaller motor with a gear reducer will work better than a larger one.

Motor shaft

Proper alignment of the motor shaft can greatly improve the performance and life span of rotating devices. The proper alignment of motors and driven instruments enhances the transfer of energy from the motor to the instrument. Incorrect alignment leads to additional noise and vibration. It may also lead to premature failure of couplings and bearings. Misalignment also results in increased shaft and coupling temperatures. Hence, proper alignment is critical to improve the efficiency of the driven instrument.

When choosing the correct type of gear train for your motor, you need to consider its energy efficiency and the torque it can handle. A helical geared motor is more efficient for high output torque applications. Depending on the required speed and torque, you can choose between an in-line and a parallel helical geared motor. Both types of gears have their advantages and disadvantages. Spur gears are widespread. They are toothed and run parallel to the motor shaft.

A planetary gear motor can also have a linear output shaft. A stepping motor should not operate at too high current to prevent demagnetization, which will lead to step loss or torque drop. Ensure that the motor and gearbox output shafts are protected from external impacts. If the motor and gearbox are not protected against bumps, they may cause thread defects. Make sure that the motor shafts and rotors are protected from external impacts.

When choosing a metal for your gear motor’s motor shaft, you should consider the cost of hot-rolled bar stock. Its outer layers are more difficult to machine. This type of material contains residual stresses and other problems that make it difficult to machine. For these applications, you should choose a high-strength steel with hard outer layers. This type of steel is cheaper, but it also has size considerations. It’s best to test each material first to determine which one suits your needs.

In addition to reducing the speed of your device, a geared motor also minimizes the torque generated by your machine. It can be used with both AC and DC power. A high-quality gear motor is vital for stirring mechanisms and conveyor belts. However, you should choose a geared motor that uses high-grade gears and provides maximum efficiency. There are many types of planetary gear motors and gears on the market, and it’s important to choose the right one.

First stage gears

The first stage gears of a gear motor are the most important components of the entire device. The motor’s power transmission is 90% efficient, but there are many factors that can affect its performance. The gear ratios used should be high enough to handle the load, but not too high that they are limiting the motor’s speed. A gear motor should also have a healthy safety factor, and the lubricant must be sufficient to overcome any of these factors.

The transmission torque of the gear changes with its speed. The transmission torque at the input side of the gear decreases, transferring a small torque to the output side. The number of teeth and the pitch circle diameters can be used to calculate the torque. The first stage gears of gear motors can be categorized as spur gears, helical gears, or worm gears. These three types of gears have different torque capacities.

The first stage helical gear is the most important part of a gear motor. Its function is to transfer rotation from one gear to the other. Its output is the gearhead. The second stage gears are connected by a carrier. They work in tandem with the first stage gear to provide the output of the gearhead. Moreover, the first stage carrier rotates in the same direction as the input pinion.

Another important component is the output torque of the gearmotor. When choosing a gearmotor, consider the starting torque, running torque, output speed, overhung and shock loads, duty cycles, and more. It is crucial to choose a gearmotor with the right ratio for the application. By choosing the proper gearmotor, you will get maximum performance with minimal operating costs and increase plant productivity. For more information on first stage gears, check out our blog.

The first stage of a gear motor is composed of a set of fixed and rotating sprockets. The first stage of these gears acts as a drive gear. Its rotational mass is a limiting factor for torque. The second stage consists of a rotating shaft. This shaft rotates in the direction of the torque axis. It is also the limiting force for the motor’s torque.

editor by czh 2022-12-01

12V made in China – replacement parts – in Ulaanbaatar Mongolia 36mm Metal Planetary Gearbox Low Speed Electric Motor with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Description:

Product Title : 36mm Pace reducer, geared motor

Gearbox Type: Planetary gears

Substance: Powder metallurgy Metallic steel

Gear Ratio : 5:1 , 10:1 , 20:1 , 25:1 , thirty:1 , 40:1 , fifty:1 , sixty:1 ,70:1…100:1… customised

Gearbox diameter : 6mm , 10mm , 12mm , 16mm , 22mm , 24mm , 32mm , 38mm , 42mm ……

3V , 12V ,24V offered .

Torque: twenty – fifty Nm, ten – 20 Nm, 5 – ten Nm,1 – 5 Nm, .5 – 1 Nm, .2 – .5 Nm, – .1 Nm, .1 – .2 Nm

D Shaft :4mm

Color : Black & silver

Custom made RPM .

We are a factory specialised in steel parts hardware & steel gearbox geared motor through powder metallurgy approach .We companies with ODM/OEM gearbox style and growth , gearmotors manufacture.

A planetary (or epicyclical) gearbox employs epicyclical gears for velocity reduction. It is composed of a single or much more toothed whee EPT turning close to a rotating shaft. Each and every rotates on its personal axis as effectively as revolving close to the central shaft. This provides great reduction ability in a tiny space, creating them frequent in computerized transmissions.These mechanisms are utilised where ever efficiency and high reduction ratios are necessary in a small area. Examples are computerized transmissions and many industrial applications employing electrical gear motors.

planetary gears also refer as epicyclic gearing consisting a few aspects sun gear, planet equipment and ring gear. Sun gear is located at the centre that transmits torque to world gears orbiting close to the sun equipment. Each systems are situated inside the ring gear. In the toothed development solar and planet gears are externally mesh and ring gear internally meshes.

Planetary equipment is identified in a lot of variation and arrangements to meet a broad assortment of velocity-ratio in the deign demands. Planetary equipment system is use in may differ applications this kind of as, clocks, lunar calendar, vehicle mirror, toys, gearhead motor, turbine motor and a lot of much more.

Planetary Gearbox advantages:

- Coaxial arrangement of input shaft and output shaft

- Load distribution to several planetary gears

- Substantial performance thanks to low rolling energy

- Almo EPT limitless transmission ratio possibilities thanks to combination of several planet phases

- Suitable as planetary switching equipment owing to fixing this or that component of the gearbox

- Likelihood of use as overriding gearbox

- Favorable quantity output

- Suitability for a wide selection of application

Software :

- Health-related and Wellness Business

- Electronics and Telecommunication Industry

- Robotics Business

- EPT Business

- CNC, Machine, and Resource EPT Industries

- Auto, Textile, Printing, Foods, and Metallurgical Industries

Geared motors for automated unit .

Personalized 6mm small geared motors , planet gearhead , metal gearbox

Workshop

The use of first equipment manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our business and the shown replacement parts contained herein are not sponsored, accepted, or created by the OEM.

Small made in China – replacement parts – in Guadalajara Mexico Size 24 * 18 mm Brushless DC Motor 6V 12V 24V with High Speed with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 various branches. For a lot more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Solution Description

Little Measurement 24 * eighteen mm Brushless DC Motor 6V 12V 24V with High-Pace Specs:

| Rated Voltage | six / 12 / 24 V |

| Velocity | 3000-ten thousand RPM (Tailored) |

| Torque | 20g.cm |

| Notice | Motor specs such as voltage, speed, torque, the shaft can be tailored. You should make contact with us if didn’t uncover a appropriate motor from our technical specs. |

Notice : It’s ju EPT the standard technological data for you reference, The specification this sort of as voltage, speed, torque, shaft can personalized.

Relevant Goods

Business Profile

HangZhou Leison Motor Co. Ltd is a manufacturer and exporter of numerous of motors with in excess of ten a long time experience.

Our product ranges incorporate:

1) DC Brush motor: 6-130mm diameter, .01-1000W output energy

two) DC Spur Gear Motor: twelve-110mm diameter, .1-300W output power

3) DC Planeary Equipment Motor: 10-82mm diameter, .1-100W output power

four) Brushless DC Motor: 28-110mm, 5-1500W output power

five) Stepper Motor: NEMA 08 to NEMA 43, Can with gearbox and lead screw

6) Servo Motor: 42mm to 130mm diameter, fifty-4000w

7) AC Equipment Motor: forty nine to 100mm diameter, 6-a hundred and forty output power

Production Tools

Certifications

Client Visit and Fair

FAQ

Q: What’s your primary goods?

A:We at the moment produce Brushed Dc Motors, Brushed Dc equipment Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors and Ac Motors and many others. You can verify the requirements for earlier mentioned motors on our site and you can electronic mail us to advocate required motors per your specification too.

Q:How to decide on a suitable motor?

A:If you have motor images or drawings to present us, or you have comprehensive specs like voltage, pace, torque, motor measurement, working manner of the motor, necessary lifestyle time and sound stage and many others, you should do not be reluctant to allow us know, then we can recommend appropriate motor for every your reque EPT accordingly.

Q: Do you have tailored provider for your regular motors?

A:Yes, we can customise for every your reque EPT for the voltage, speed, torque and shaft dimension/form. If you want further wires/cables soldered on the terminal or require to incorporate connectors, or capacitors or EMC we can make it too.

Q:Do you have specific style service for motors?

A:Of course, we would like to layout motors individually for our buyers, but it might require some mould charge and design demand.

Q:Can I have samples for tests first?

A:Indeed, undoubtedly you can. After confirmed the essential motor specs, we will estimate and give a proforma invoice for samples, when we get the payment, we will get a PASS from our account section to move forward samples accordingly.

Q:How do you make confident motor quality?

A:We have our possess inspection procedures: for incoming supplies, we have signed sample and drawing to make sure qualified incoming materials for production method, we have tour inspection in the procedure and closing inspection to make sure competent merchandise ahead of shipping.

Q:What is your guide time?

A:Usually speaking, our normal common merchandise will require 25-30days, a bit for a longer time for customized merchandise. But we are really flexible on the lead time, it will depends on the particular orders

Q:What’s your payment phrase?

A:For all our new buyers, we will want 40% deposite, 60% paid out prior to shipment.

Q:When will you reply after received my inquiries?

A:We will response in 24 hrs when get your inquires.

Q:How can I tru EPT you to make certain my cash is protected?

A:We are qualified by the third get together SGS and we have exported to more than eighty five countries up to June.2017. You can check our popularity with our current buyers in your country (if our buyers do not mind), or you can purchase by way of alibaba to get trade assurance from alibaba to make confident your money is safe.

Q:What is the minimum order quantity?

A:Our minimum purchase quantity relies upon on diverse motor types, make sure you e-mail us to check. Also, we generally do not take personal use motor orders.

Q:What is actually your shipping and delivery method for motors?

A:For samples and deals significantly less than 100kg, we normally sugge EPT specific transport For heavy deals, we typically sugge EPT air shipping or sea shipping. But it all is dependent on our customers’ requirements.

Q:What certifications do you have?

A:We at present have CE and RO EPT certifications.

Q:Can you send out me your cost record?

A:Since we have hundreds of diverse goods, and cost differs for every different specs, we are not ready to offer you a price listing. But we can estimate in 24 several hours as soon as got your inquirues to make sure you can get the price in time.

Q:Can I visit your business?

A:Yes, welcome to visit our firm, but you should permit us know at lea EPT two months in progress to support us make confident no EPT conferences during the day you pay a visit to us.

Many thanks!

Speak to Us

HangZhou Leison Motor Co.,Ltd

Speak to Particular person: Celia Chen

Tel: +86-571-27835797

Any e mail or trademanager inquires will be replied within 24 hrs.

Standard samples can be offer really swiftly(in 10 days)

Customized support for type of motor accoring to your requirement

Skilled Tchnical assistance and After-sale provider

Sourcing motor components like gears, encoders, cables, connectors and so on

The use of first gear manufacturer’s (OEM) portion figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our firm and the detailed alternative areas contained herein are not sponsored, accepted, or manufactured by the OEM.

DC made in China – replacement parts – in Alexandria Egypt Brushless Motor with Controller with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 different branches. For more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

DC Brushless Motor with Controller

PG36M555 Sequence

voltage: 3VDC 6VDC 9VDC 12VDC 24VDC

Velocity variety: 3000-9500rpm

energy: 3.3-13w

Standard purposes: Central air-conditioning valve, Amusement equipment, Coin

Refund products, Grill, Oven, Peristaltic pumps, ATM lender

Automatic program, Robot, Healthcare equipment, Office

Products, House appliances, Computerized actuator.

Fat: 320~400g/PCS(approx)

Packing particulars: CTN measurement: 32X28XH26cm 40PCS/CTN G. W. 16Kgs

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Organization Introduction

The use of first tools manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our organization and the outlined substitution parts contained herein are not sponsored, approved, or created by the OEM.